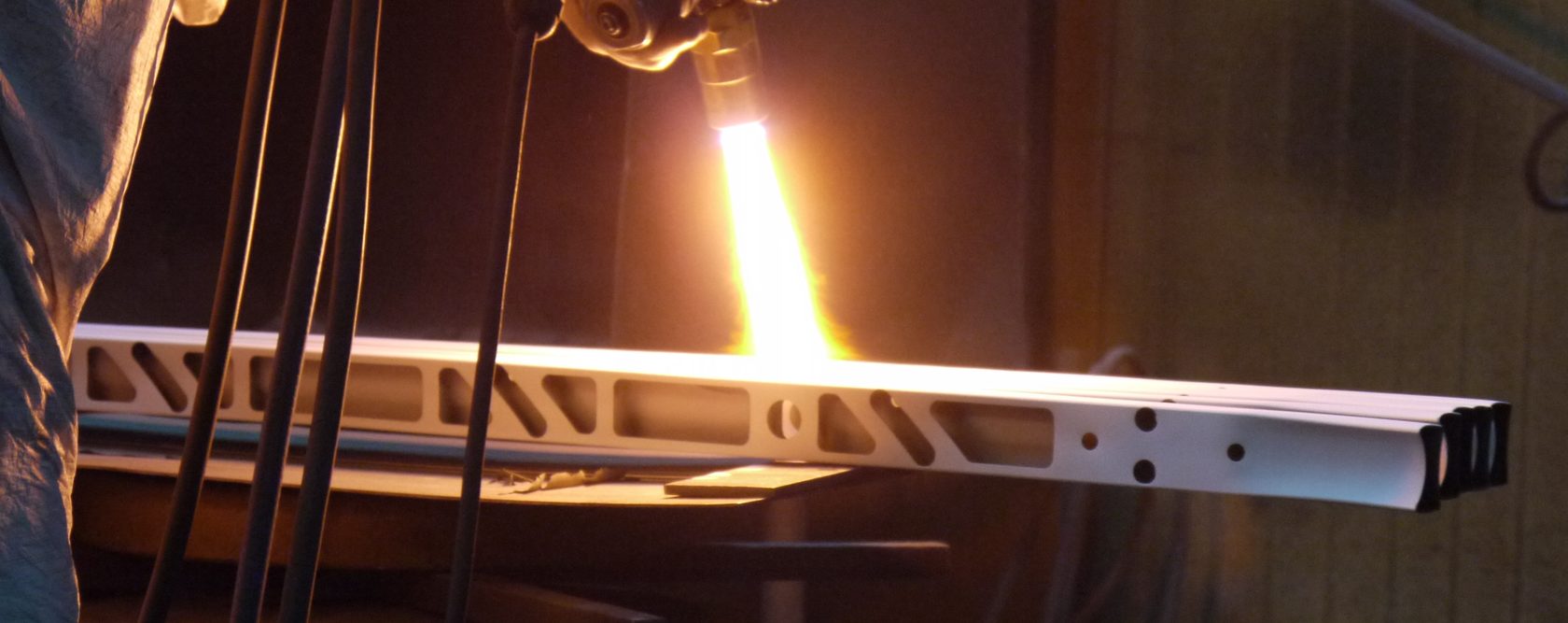

Das Drahtflammspritzen ( WFS )

Beim Draht- oder Stabflammspritzen wird der Spritzzusatzwerkstoff im Zentrum einer Brenngas-Sauerstoff-Flamme kontinuierlich aufgeschmolzen. Mit Hilfe eines Zerstäubergases, z.B. Druckluft oder Stickstoff, werden aus dem Schmelzbereich die tröpfchenförmigen Spritzpartikel abgelöst und auf die vorbereitete Werkstückoberfläche geschleudert. Das Flammspritzen mit Draht ist ein verbreitetes Verfahren mit einem sehr hohen Spritzschichtqualitätsstandard

Das Pulverflammspritzen ( PFS )

Beim Pulverflammspritzen wird der pulverförmige Spritzzusatz in einer Brenngas-Sauerstoff-Flamme an- oder aufgeschmolzen und mit Hilfe der expandierenden Verbrennungsgase auf die vorbereitete Werkstückoberfläche geschleudert. Falls erforderlich, kann zur Beschleunigung der Pulverteilchen auch noch ein zusätzliches Gas (z.B. Argon oder Stickstoff) verwendet werden. Die Vielfalt der Spritzzusatzwerkstoffe ist bei den Pulvern mit weit über 100 Materialien sehr weit gefächert. Bei den Pulvern unterscheidet man selbstfließende und selbsthaftende Pulver. Die selbstfließenden Pulver benötigen meist zusätzlich eine thermische Nachbehandlung. Dieses "Einschmelzen" erfolgt überwiegend mit dem dafür hervorragend geeigneten Brenngas-Sauerstoff-Flammen. Durch den thermischen Prozess wird die Haftung der Spritzschicht auf dem Grundwerkstoff erheblich gesteigert; die Spritzschicht wird gas- und flüssigkeitsdicht.

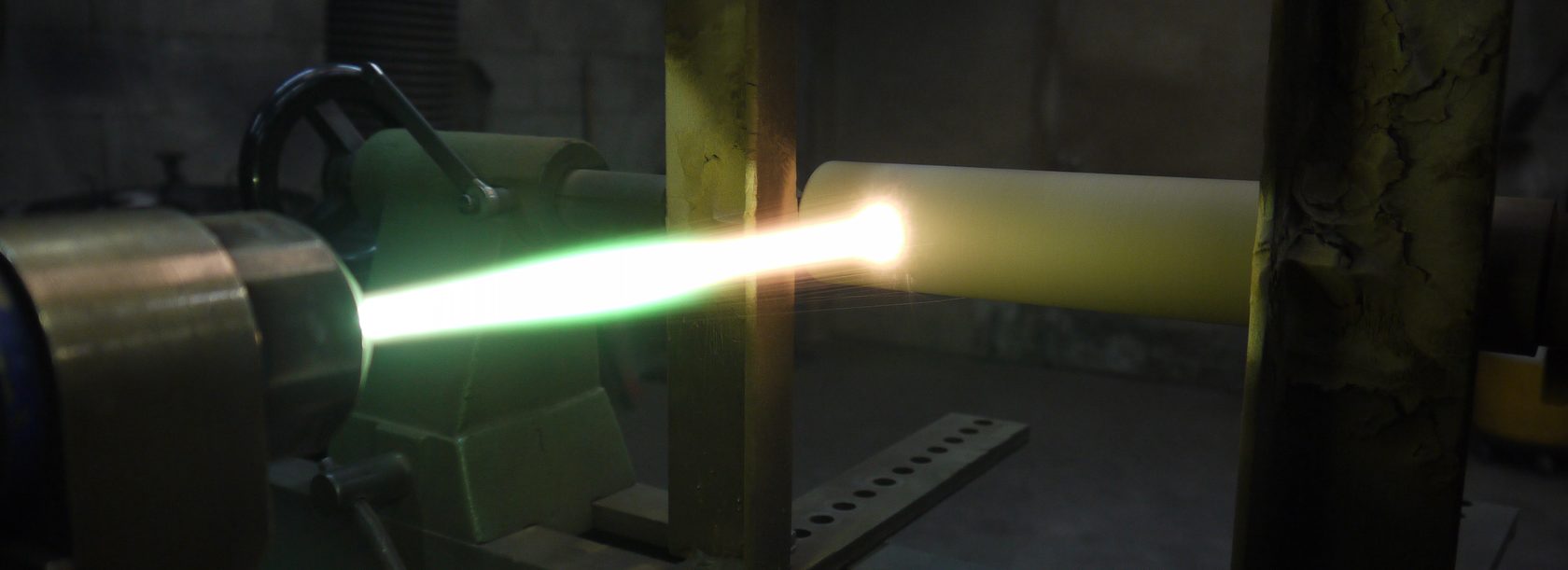

Das Lichtbogenspritzen ( AS )

Beim Lichtbogenspritzen werden zwei drahtförmige Spritzzusätze gleicher oder unterschiedlicher Art in einem Lichtbogen abgeschmolzen und mittels Zerstäubergas, z.B. Druckluft, auf die vorbereitete Werkstückoberfläche geschleudert. Das Lichtbogenspritzen ist ein leistungsstarkes Drahtspritzverfahren, bei dem aber nur elektrisch leitende Materialien verspritzt werden können. Bei der Verwendung von Stickstoff oder Argon als Zerstäubergas wird eine Oxydation der Materialien weitgehend unterbunden.

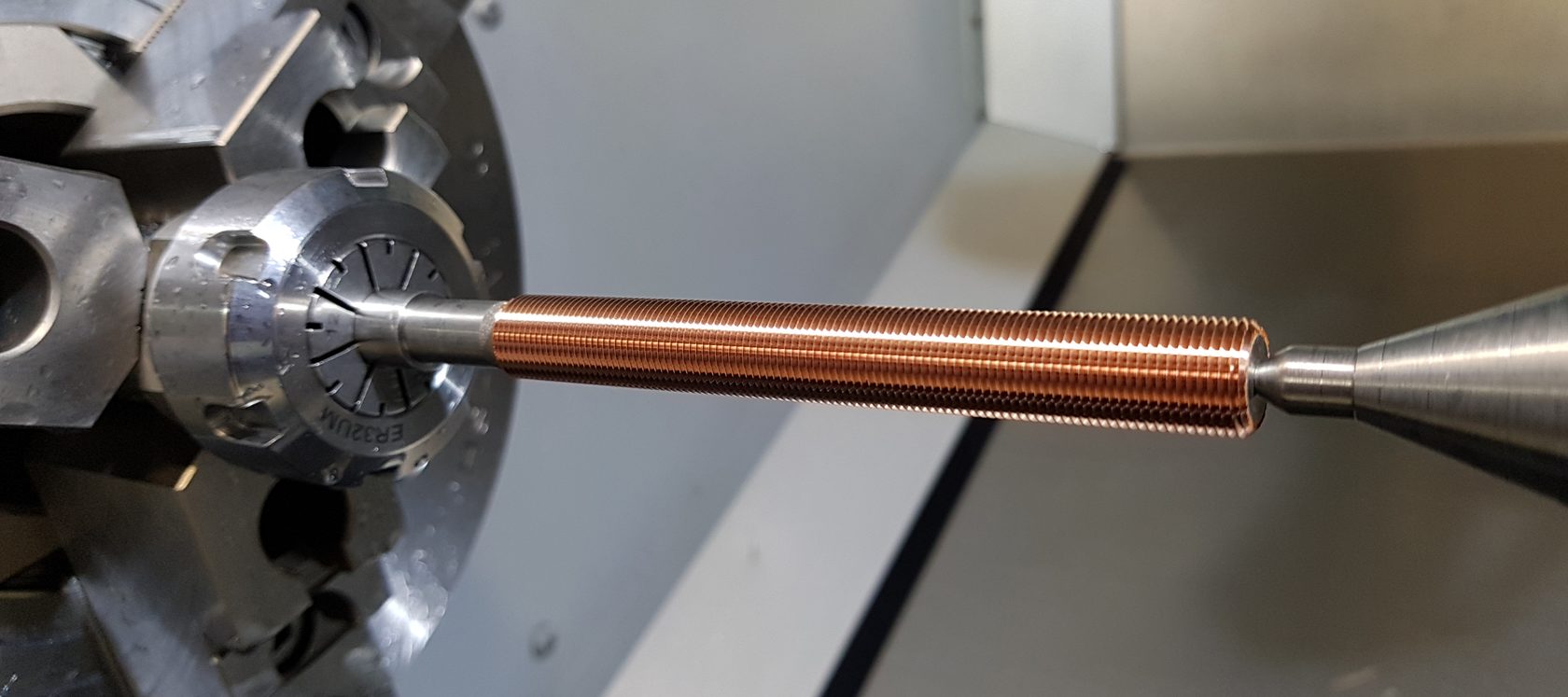

Das Hochgeschwindigkeitsflammspritzen ( HVOF )

Beim Hochgeschwindigkeitsflammspritzen erfolgt eine kontinuierliche Gasverbrennung mit hohen Drücken innerhalb einer Brennkammer, in deren zentraler Achse der pulverförmige Spritzzusatz zugeführt wird. Der in der Brennkammer erzeugte hohe Druck des Brenngas-Sauerstoff-Gemisches und der meist nachgeordneten Expansionsdüse erzeugen die gewünschte hohe Strömungsgeschwindigkeit im Gasstrahl. Dadurch werden die Spritzpartikel auf die hohen Partikelgeschwindigkeiten beschleunigt, die zu enorm dichten Spritzschichten mit ausgezeichneten Hafteigenschaften führen. Durch die ausreichende, aber moderate Temperatureinbringung wird durch den Spritzprozess der Spritzzusatzwerkstoff nur gering metallurgisch verändert, z.B. minimale Bildung von Mischkarbiden. Bei diesem Verfahren werden extrem dünne Schichten mit hoher Maßgenauigkeiten erzeugt. Als Brenngase können Propan, Propen, Ethylen, Acetylen und Wasserstoff verwendet werden.

Das Kaltgasspritzen ( CGS )

Beim Kaltgasspritzen wird ein Gas, z.B. Stickstoff, auf extrem hohe Geschwindigkeiten beschleunigt. Danach wird das gewünschte Material in Pulverform zugeführt. Beim Kaltgasspritzen treffen die Spritzpartikel bei mehrfacher Schallgeschwindigkeit auf das Substrat auf und bilden durch die enorme kinetische Energie eine dichte, fest haftende Schicht. Die entstandenen Schichteigenschaften unterscheiden sich vom Ausgangsmaterial fast nicht mehr, es sind keine Poren vorhanden.

Das Plasmaspritzen ( APS )

Im Gegensatz zu den thermischen Spritzverfahren mit Flamme oder Lichtbogen, die Temperaturen zwischen 3000 und 4000 °C erreichen, hebt sich das Plasmaspritzverfahren vor Allem durch die Temperaturen hervor, die hier erreicht werden.

Im Plasma, welches man durch Ionisieren eines Gases wie Argon oder Wasserstoff erhält, herrschen ca. 20.000 °C. Daher eignet sich dieses Verfahren hervorragend, um Werkstoffe mit hohem Schmelzpunkt zu verarbeiten. Nur im Plasmastrahl lassen sich keramische Pulver aufschmelzen, um auf dem Substrat eine dichte, fest haftende Schicht zu bilden. Alle anderen Spritzverfahren sind dazu nicht geeignet.

Bei den Metallen lässt sich vor Allem Wolfram erwähnen, welches sich mit einem Schmelzpunkt von 3400 °C nur mittels Plasmaspritzverfahren verarbeiten lässt. Wolframschichten sind säurebeständig und abbrandfest.